How to sharpen chain saw with a chainsaw file

Two great reasons to sharpen the chain.

– low power consumption & high efficiency.

The current logging work, from axe to chainsaw, has improved by more than one magnitude. There are some more saw monsters with mechanical arms, cutting trees just like cutting melons and vegetables, refreshing our old minds of in seconds.

Our life is already hard enough, but the working problems always make us even more anxious. So, we need good enough tools to make our work more efficient. Rather than waste our precious time and energy on dull tools.

The working environment of lumberjacks is unimaginable for many people. Sometimes, they have to go to the mountains where human are rarely seen. Sometimes, they have to go to the primeval forests where there are many weeds. Sometimes, they have to climb to the top of the slender trees. Sometimes, they have to repair the municipal trees on the streets of the city under the scorching sun. It sounds not simple, and such a work intensity requires very lightweight sharp handy tools.

Here we suggest a round chainsaw file for sharpen your saw chain in everywhere you working!

It can be imagined that if you have reached the top of the tree and started the chain saw engine, but just found that the saw is very dull, the sour taste can only be understood by your own experience. As the saying goes “if want to work well, we must first sharpen our tools”. If the saw chain becomes blunt, it will directly lead to energy consumption increased and excessive wear of the machine, reducing the using life of the chain saw.

How to sharpen the saw chain?

Here are all the secret scripts of grinding chain you want to know.

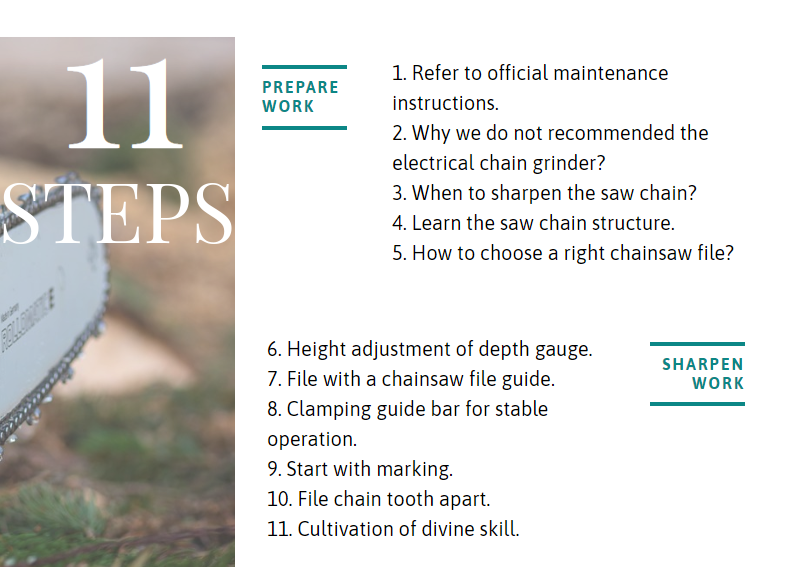

What you will learn in this article.

Click the corresponding item to jump to the item directly.

- Refer to official maintenance instructions.

- Why we do not recommended the electrical chain grinder?

- When to sharpen the saw chain?

- Learn the saw chain structure.

- How to choose a right chainsaw file?

- Height adjustment of depth gauge.

- File with a chainsaw file guide.

- Clamping guide barfor stable operation.

- Start with marking.

- File chain tooth apart.

- Cultivation of divine skill.

- Refer to official maintenance instructions

First important thing, of course, you need to look at the user manual before start to do any work. What we are talking about here is the official manual. After all, no one knows their product features better than factory themself. Moreover, the current technology is improving so faster than ever before. We especially need to pay more attention to prevent some unnecessary troubles for some new tools. Here we take STIHL chain saw as an example. Of course, it will be better if you have printed instructions. Follow the instructions step by step to finish the maintenance, at least you will avoid many detours.

The progress from axe to chainsaw is probably the biggest evolutionary leap in tools history. Think about it, It seems that just overnight, the task of cutting down big trees has been changed from time-consuming and labor-intensive work to an amazingly fast and effortless high-tech industry.

Today, chainsaws are often used by both professional loggers and DIYers to cut trees, trim trees or cut wood. But even with the largest and most powerful saw machines, no body want to cut with a blunt teeth. Here is a good news, unlike most other power tools, you can sharpen the saw chain tooth in a few minutes to adapt to the new cutting task.

- Why we don’t recommended the electrical chain grinder?

Grinding the chain by hand with a file seems to be a slow method. However, once you master this simple skill, it would really be a more convenient and direct ways than any others.

Someone use electrical chain grinder, but in my opinion, that sharpening effect is not so good and there is no need for that kind of fuss.

- We can’t feel the strength like human handsif use power tools. What it cutis either too much or too little. Finally, we need to do it again manually. Brother, Why we make such troubles for ourselves!

- The final edgeangle is not as accurate as hand file,and it will be first worn out by the chain grinding machine before we used them up, causing great loss.

- It is inconvenient to carry a grindingmachine because of itsheavy weight. It also needs to provide stable power supply, which also limits the situation of use.

- Finally, if you don’t have to grind a lot of chains every day, it’s really not recommended to use a electrical machine to grind. A fileis perfect for the task.

- When to sharpen the saw chain?

It’s surely important to keep the chain saw sharp, so when do we need to maintain the chains?

- a. The chain cannot enter the cut smoothly, it has to be forced into the cut by applying pressure to the engine head. If you have this feeling, the work begins to be laborious.

- b. The chips produced during sawingbecome fine dustinstead of thick wood chips.

- c. Even though the chain sawhas been well lubricated and propsaw has vibration noise or rebound phenomenonwhen cutting, at this time, the depth gauge size needs to be checked.

In case of the above situations, we need to check the chain and maintain it in time.

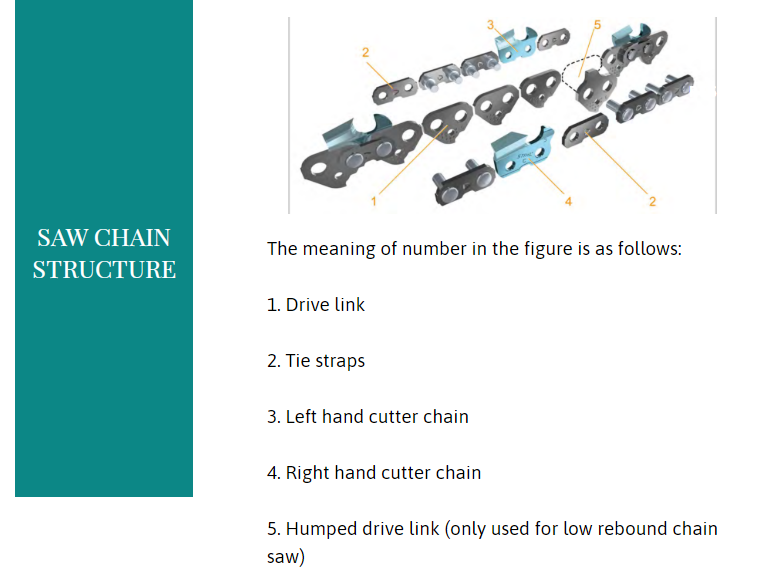

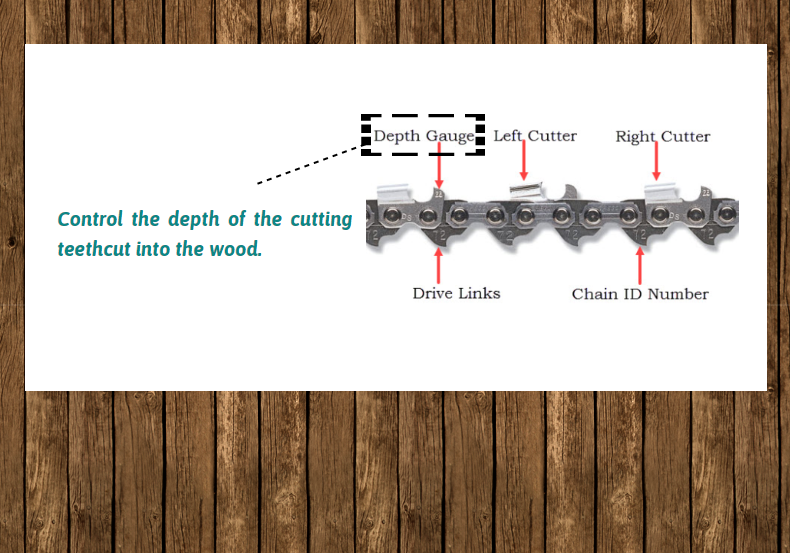

- Learn the saw chain structure.

First of all, let’s understand the chain structure. Let’s take STIHL as an example.

STIHL saw chains are three-link chains and always assembled in the same basic pattern. They are different in the shape of the cutters and the dimensions of the individual links. As shown in the figure above.

- How to choose a right chainsaw file?

Before sharpen the chain, you need to know two specifications:

- Diameter of semicircle cutting edges on the saw chain.

The information can be found in the chain saw user’s manual or just ask the dealer.

First, look at the chain carefully and you will see a series of teeth with sharp semicircle cutting edges. The diameter of the edge varies according to the saw model, but it is usually 5 / 32 inch (corresponding to 4.0mm), 3 / 16 inch (4.8mm) or 7 / 32 inch (corresponding to 5.5mm). There are also some special models, 11 / 64 inch (corresponding to 4.5mm), 13 / 64 inch (corresponding to 5.16mm), 1 / 4 inch (corresponding to 6.3mm), 9 / 32 inch (7.0mm), 5 / 16 inch (corresponding to 7.9MM). These are rare. 4.0mm, 4.8mm and 5.5mm are the most common ones on the market.

In order to polish these curved cutting edge teeth, it is necessary to use a special size round saw file with diameter matching.

Here we take STIHL as an example to illustrate the selection method of file.

Check the numerical code of the chain saw pitch outside the depth gauge, and then refer to the following table to obtain the chain saw pitch, corresponding to find the diameter of the file.

| Numerical code on the outside of depth gauge | chain saw pitch | round file diameter |

| 1 | 1/4″ | 4.0mm |

| 2 | .325″ | 4.8mm |

| 3 | 3/8″ | 5.2mm |

| 4 | .404″ | 5.5mm |

| 6 | 3/8″ picco | 4.0mm |

| 7 | 1/4″ picco | 3.2mm |

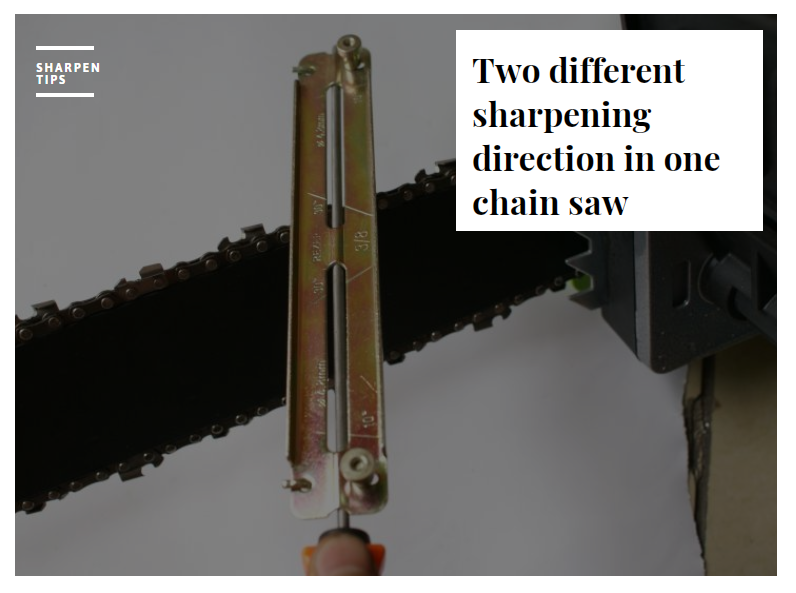

In addition, note that the top of the cutting teeth is tilted at alternate angles, which means one tooth tilts to the left and the other to the right.

- Height adjustment of depth gauge

Between each of the cutting teeth is a flat piece of metal, shaped a bit like a shark’s dorsal fin.

By the way, our SHARKY TOOLS LOGO also comes from shark’s dorsal fin.

These parts, known as “depth gauges,” are slightly shorter in height than the cutting teeth. Depth gauges do not require sharpening; they are used as depth gauges to control the depth at which the cutting teeth cut into the wood. This part needs to be adjusted with the flat chain saw file.

- File with a chainsaw file guide.

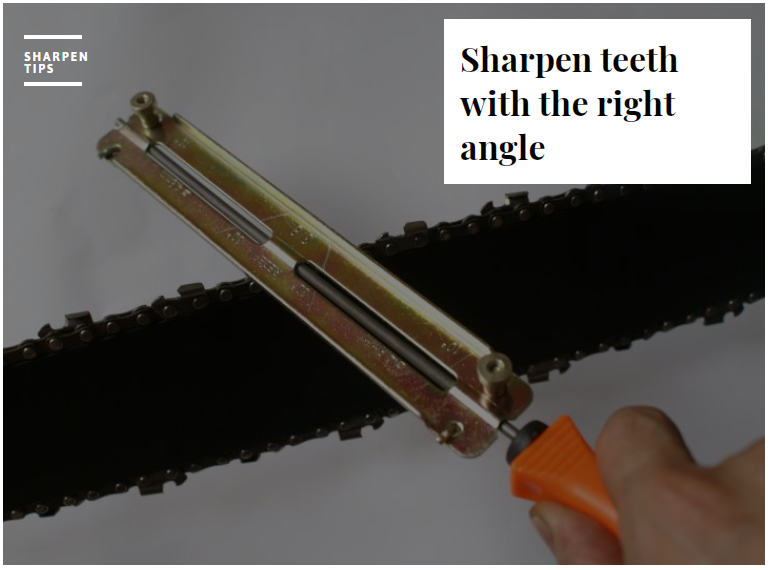

In order to ensure consistent and accurate results when filing the chain manually, the file can be installed in the chain saw file guide(if you are an old driver, pls ignore,you file by your own hand only). The guide has two purposes: it provides a flat surface for holding the file on the saw chain and controlling the depth at which the file can be cut. The stamping mark on the bracket shows the diagonal line corresponding to the spacing or cutting angle of the saw chain teeth.

First, select a circular chain saw file that matches the diameter of the semicircular edge on the cutting teeth. Loosen the set screws on the file guide and slide the file under the two metal press clips. Tighten the screws to secure the file in the guide rail.

- Clamping guide barfor stable operation

Connect the chain brake and clamp the guide plate of the chain saw with a bench vice or a special clamp, so that it is more stable in the process of operation and more efficient with less labor. If it is a cordless electric saw, please take out the battery pack for safety.

- Start with marking

Next, mark the first tooth to be ground with a marker, just a simple mark, to let you know where you first started grinding.

Place the file holder on top of the saw chain so that the file rests against the ink marked with the semicircular cutting edge. Adjust the guide until the diagonal line stamped on the top of the guide is parallel to the cutting edge on the top of the saw chain. Now, while maintaining this angle, grind the cutting teeth from the inside out of the file. Note that the file should be used against the front!!! Do not press down hard when pulling back, otherwise it will cause damage to the file teeth and affect the service life. In addition, the file should be rotated gently and regularly to avoid excessive wear on one side of the file.

Repeat five or six times, with slow, steady force, count how many times you file on the first serration, and grind the same number of times on all other serrations. After proper and proper grinding, the whole curved cutting edge should be clean and glossy.

- Filechain tooth apart

After filing the first serration, skip the next serration and file the third. Remember, the blades on the serrations alternate left and right. So it’s better to grind every other place, so you don’t have to change the angle of the file all the time, and the efficiency will be greatly improved. Continue in this way, filing every other place until you get back to the start of the saw chain. Now, move to the other side of the console and start filing the sawtooth that was skipped the first time you moved.

- Cultivation of divine skill

At the beginning of using the file, you may feel uncomfortable. It’s like Duan Yu’s six pulse sword in martial arts novels. At the beginning, you can’t receive and send it freely. But after a while, you will feel that the feeling of feeling the strength on your hand will make you unable to stop. It’s the spiritual communication between you and the chain through the file. Once you master this technology, you can sharpen most of the chain saw chains in less than 15 minutes, so as to achieve the goal of “sharpening the knife without mistaking the woodcutter”.

What about? Guys, have you learned?

Some of the pictures and words in the article are from the Internet.

If there is any infringement, please contact the author (Whatsapp/tel: 15713295989),

the main reference resources,